Besides protecting loads from mains disturbances, like surges, swells and harmonics, primary UPS goal is to seamlessly deliver power during a prolonged mains fault. Battery packs are put in place in order to meet the required back up time and regardless of technology and chemistry they are usually the most expensive part of the whole UPS system. A deep understanding on which UPS parameters are involved in assessing the required battery power is paramount to perform accurate sizings, which in turn can allow for considerable savings.

Real power and backup time.

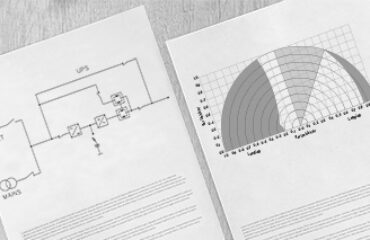

A UPS can be defined as a static electronic converter, which purpose is to deliver real power to the loads. Double conversion UPS’s are based on a dual stage conversion. A first stage – rectifier or AC/DC converter –drawing power from the mains and delivering it to the DC link, which is connected to the battery system. A second stage – inverter or DC/AC converter – which uses DC power to generate clean AC power for the connected loads. In both conversion stages a little amount of power is turned into heat inside both converters. This is usually referred to as rectifier and inverter “losses”. As far as battery operation is concerned, inverter losses should be accounted for in the deliverable battery power to meet the required backup time. This can be accomplished by dividing the required load power by the inverter efficiency factor. Thus adding on top of the count all the power that will be lost in the DC/AC converter throughout the discharge process.

Preventing battery blocks’ damages.

Battery blocks can be defined as chemical energy storage systems. They are usually charged up to their maximum energy capacity, they are combined in a matrix of strings and parallels, to build up the required DC voltage and energy amount to be discharged upon mains failures. During discharge, power is transferred from battery to loads, resulting in a decrease of the blocks voltage. This process must stop before the absolute maximum end of discharge voltage is reached, to prevent blocks’ severe damage. The end of discharge voltage range defines the so-called DoD (Depth of Discharge), or the extent to which a battery is discharged. Due to the chemical form of the energy storage, available discharge power is a non-linear function of discharge time duration and end of discharge voltage.

The longer the discharge, the smaller the available power is. The lower the end of voltage, the bigger the deliverable power is. Such relationship is charted in typical battery discharge tables, where battery manufacturers state the deliverable power for the allowed backup times and end of discharge voltage range. On the other hand, UPS manufacturers state the minimum DC voltage their inverter can operate at. This figure should match the selected battery end of discharge voltage, sometimes referred to as inverter cut-off voltage, allowing battery solutions to be properly sized.

Battery recharging and UPS sizing.

After a discharge, batteries are to be restored to their nominal capacity through a charging cycle performed by UPS AC/DC converters. The time it takes to fully restore battery capacity is related to the applied charging current. As far as VRLA batteries are concerned, typical required charging current for restoring full capacity within 8 hours is 0.1C, where C is the total battery capacity in Ampere-hours. In UPS systems rectifiers must be able to supply their nominal output power, while charging the connected battery. If the above typical charging time is to be met, the rectifier available charging current of the selected UPS must be equal or exceed the battery’s 0.1C figure. If not the case, an appropriate UPS oversizing is to be applied. Some UPS manufacturers have developed a dedicated feature to allow rectifiers diverting any unused output power to battery charging, thus limiting the need for oversized units.

For more information on sizing a Borri UPS please email us at info@borri.it.

Italiano

Italiano  Русский

Русский  Deutsch

Deutsch